eVTOL Testing

Mustang Advanced Engineering (MAE) can supply eVTOL testing equipment for many different components and testing applications. Due to confidentiality/Non-Disclosure agreements, MAE cannot release actual pictures of certain test cells, test stands, and/or components.

- Component Testing:

- Electric Motors

- Motor Control Units (MCU’s)

- Gas Turbine Power Unit

- Gearboxes

- Battery and/or Fuel Cells

- Battery & Fuel Cell Management Systems

- DC/DC Power Supplies

- Fuel Delivery and Storage Units

- Hydrogen Delivery and Storage Unit

- Assembly Testing

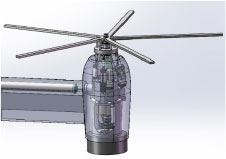

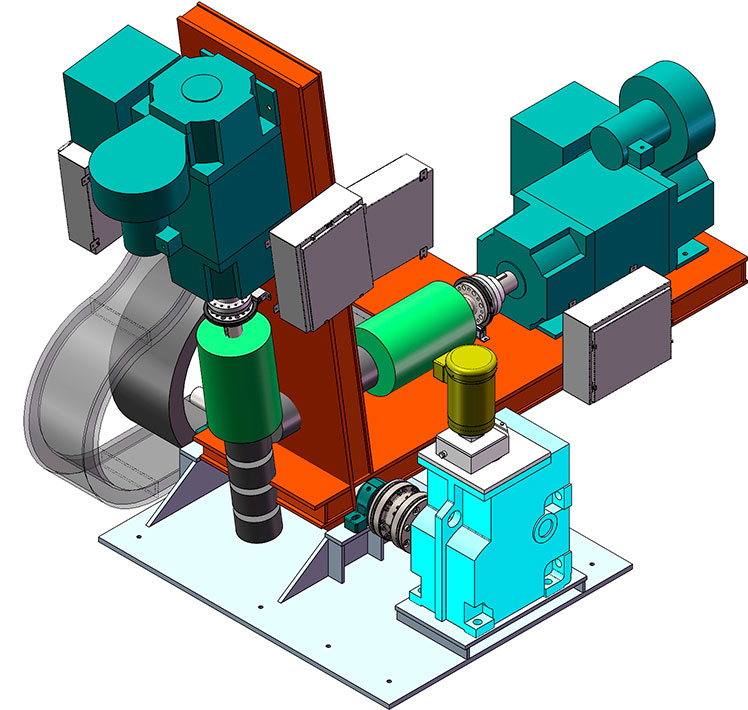

- Rotor Head Assembly with Test Stand Motor and Hydraulic Actuator Controls

- Rotor & Electric Motor Assemblies Performance Testing

- Electric Motor Assemblies (Motor, Gearbox, MCU, Batteries, Gas Turbines)

- Avionic Control of Single and Multiple Coupled Assemblies

- Fuselage Testing

- Electrical Wiring Harness Testing

- Software Simulation of Multiple Missing Sub Systems.

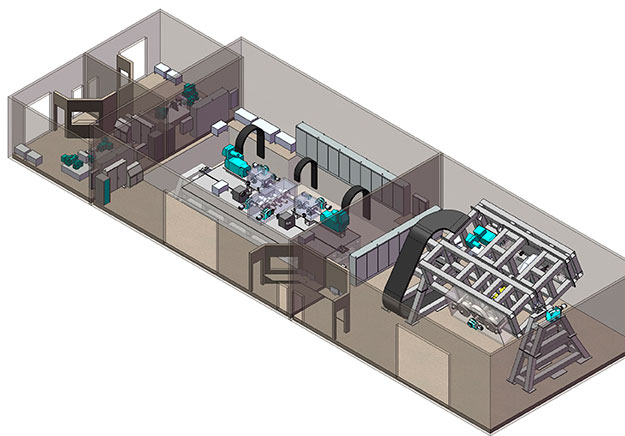

- Complete eVTOL testing mounted on a tethered support stand with 6-dof measurement and rail movements within a variable direction wind tunnel.

- Avionics Control and Flight System Testing

- Durability and Stress Testing

- Range Validation

- Take-off, Landing and in-Flight Simulation

For the innovative air mobility (IAM) industry has required vehicles to meet three essential tests for eVTOL to be certified:

- Flight vibration testing (FVT)

- Ground vibration testing (GVT), modal and structural analysis

- Wind Tunnel testing

MAE is an excellent resource for such testing including IAM’s suggested additional tests like

- Propulsion system testing, especially for electric motors

- Energy storage systems testing, including battery thermal runaway

- Shell testing, covering all aspects of the aircraft housing, such as the blades, wings, flight controls, ground support, fuselage, recovery system, and payload system

- Electronics testing, including all kinds of sensors and stabilization devices

- Crash testing, covering impact and forces involved

- Noise testing, a central parameter when considering social acceptance

MAE Supplied Test Cell and Test Stand Equipment

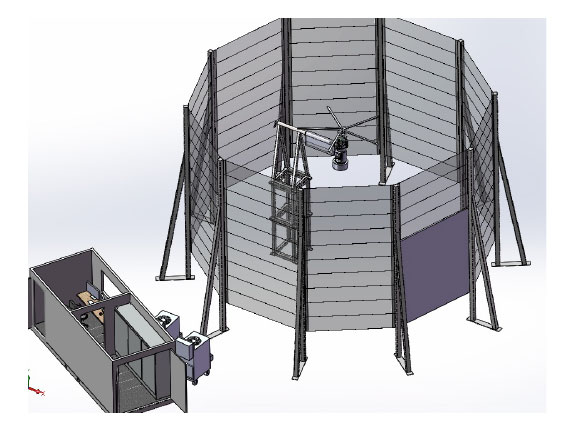

Figure 1 – Fixed Location Rotor Test Stand with or without 98° Rotor Assembly Rotation Conceptual View

- Laboratory Battery Testing and Fuel Cell Testing

Reference MAE brochures for DC power supplies used in MAE’s battery simulators and battery exerciser applications. MAE supplies standard single and dual range DC power supplies. MAE offers between 28 VDC to 1,200 VDC as standard, with custom higher voltage DC power suppliers available as modified standard products. The DC power supply is the same for the battery simulator and the battery exerciser with just different software applications. MAE provides safety voltage bleed down circuits with cover locking mechanisms to restrict access to the physical cable connector to the unit under test (UUT) until the voltage at the connector is less than a user configurable value below 50 VDC which is the safe voltage level.

- Laboratory Gas Turbine Testing with or without Power Unit:

MAE has produced gas turbine loading dynamometers for the past 35-years and can easily handle your gas turbine testing requirements. MAE can supply all of the support items; fuel delivery systems, loading dynamometers, fluid cooling systems, actuator controls, ECU interfaces, etc. If the power conversion unit is attached to the gas turbine, MAE can cable the power conversion unit to:

- MCU & battery combination which is controlled by a battery management system

- DC power supply to convert the electrical generator power to either AC back to the facility power grid or burn the power off through resistive braking, or other forms of power dissipation can be performed.

- Production Electric Motor Test Stand (vertical, horizontal or variable rotation stands)

- Production Gas Turbine Power Unit Test Stand

Reference MAE’s brochures; MAE can produce production gas turbine test stands to measure the performance and durability of your gas turbine. MAE can also supply all of the support systems to operate the gas turbine

- Production MCU Test Stands

MAE can supply a MCU test stand with a DC power supply and test stand motor with a dynamometer to perform loading on the MCU. MAE can also perform phase to phase and phase to ground resistance tests on the MCU. Control interfaces to the MCU include CAN, CAN FD, MIL STD 1553, or ARC interfaces. MAE can also flash the MCU software.

- Production Gearbox Test Stands

MAE has produced gearbox test stands for the past 35-years and can easily handle your gearbox testing. MAE has built multiple helicopter main transmission and tail rotor test stands.

MAE Supplied Software System for Laboratory and Production testing.

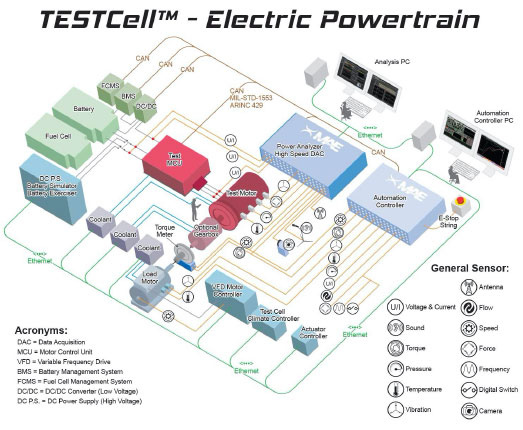

- MAE’s TESTCell™ software system is able to integrate the entire test cell including the automation controller, high speed data acquisition, power analyzers, high speed cameras, vibration analysis packages, test cell climatic control systems and facility interface controllers into a single control and data acquisition system with custom reporting.

- POWERStand™ software is primarily an automation controller with a DAC system capable of controlling a single EV test stand with control and data acquisition requirements associated with the UUT and the test stand. This software is normally associated with a single test stand not requiring high speed data acquisition.

- POWERTrain™ software is primarily an automation controller with a DAC system for transmissions, gearbox, and powertrain testing capable of controlling a single test stand with control and data acquisition requirements associated with the UUT and the test stand.

- EOLTest™ is MAE’s production test stand software used in a single position test stand.

- MAPS2™ is MAE’s full manufacturing automation process & test sequencing software system which is used for multiple position assembly and testing of a UUT during production.

- TESTApp™ is MAE’s test application software used to configure a test stand and allows for a customer’s test cell or test stand software to command the set points to the test stand while the TESTApp™ controls the test stand and test stand support items. These applications are powerful tools used to integrate with customer supplied software.

- TESTWeb™ follows the recent trend of web based software applications, which allows the customer from anywhere with an internet connection to configure a test sequence and down load the test sequence into the dyne.