Vertical Lift & Whirl Towers, testing for VTOL (vertical take-off and landing) and rotorcraft development, such as main rotor hub system development and performance analysis such as blade lift/thrust or blade hover envelope during varying or constant blade speeds. The Whirl Tower can be simple or complex system, small or large depending on the customer requirements. Blade systems can be developed for large manned and smaller unmanned (Drone) system. All this is important aspects of eVTOL, electric and hybrid aerospace development.

Small systems can operate blades at thousands of rpms while large systems typically operate under 250rpm. Current and future research and development on blades and propellers keep researches constantly evaluating materials, active blade structural and to reduce ice formation, sound, balance and vibration. Through the use of these Whirl Towers increase blade and main rotor hub systems efficiencies are determined smaller diameter, high power and higher speeds blade systems are being developed and require validation and testing. Counter rotating Co-Axial rotor testing system can be supplied for testing blades and full head development.

Whirl Tower Systems can vary in size from small single digit Hp (kW) to large thousands of Hp (kW). MAE can supply your next Whirl Tower System. MAE has the engineering, manufacturing, construction and field support capabilities to be your supplier. We can repurpose, up-grade an existing facility or start from scratch.

Whirl Tower Features:

- Bi-directional Operation

- Scalable Power Capabilities up to 25,000Hp (18,750kW)

- Unique Rotor Head Design and Mounting for Reduce Structural Vibration

- Ultrahigh Accuracy Rotor Head and Pitch Control Sensors with Telemetry system

- Remote Mounted Laser Blade Measuring System with Pulse Marked High Speed Camera available.

- Designed with Weather Resistance Material and Enclosures for Temperature Control as required.

- Vestal and Fast Blade Lift System for Quick Blade Interchange.

MAE supplies Test Stands, Software & Controls, Test Cell Support Equipment, Engineering Services, Installation Services and Refurbish Services to many portions of the Military and Aerospace Industry. Our commitment, applied ingenuity, supply of equipment & services to these Industries, has made MAE a premier supplier to these Industries.

MAE has supplied many integrated Standard and Engineered Test Stands to the Military and Aerospace Industry. We have also supported the Industry with Test Article Support Equipment, Test Cell Support Equipment, Software, Control and Data Acquisition Systems, Facility Support Equipment, Installation & Training Support as well as Turnkey Systems. MAE has work with many Customers as the prime contractor, subcontractor and simple component supplier.

MAE is a 35 plus year old vertically integrated United States of America manufacturing and engineering company with turnkey capabilities. We use a proven and logical approach to develop and manufacturing equipment to meet our Customers’ requirements and needs. Over the past 35 years we have developed many testing and software solutions to draw experience from in developing new solutions to our Customer’s specifications and needs. Some of these solutions are modified existing projects or totally new concepts solutions whereby MAE uses in-house expertise and out-of-house expertise coupled with the Customers knowledge and needs to develop a solution.

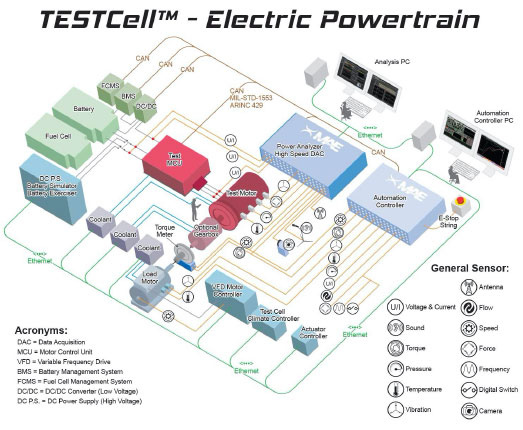

eVTOL Testing Systems

MAE has extensive background developing test systems for the validation of electric vertical take-off and landing vehicles and components, including electric, hybrid and standard vehicles

Component Testing:

- Electric Motors

- Motor Control Units (MCU’s)

- Gas Turbine Power Unit

- Gearboxes

- Battery and/or Fuel Cells

- Battery & Fuel Cell Management Systems

- DC/DC Power Supplies

- Fuel Delivery and Storage Units

MAE Competencies

- Engineering

- Project Management

- Mechanical

- Electrical

- Software

- Control

- Hydraulics

- Architecture

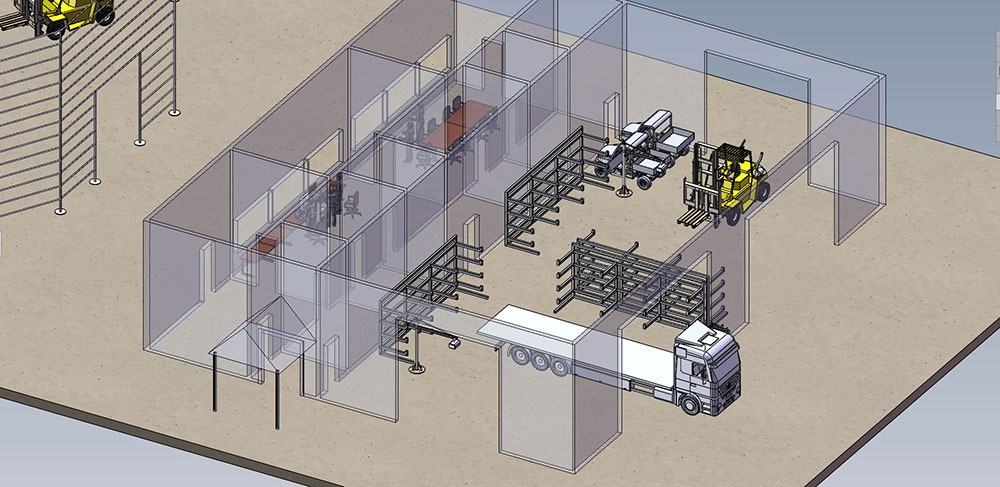

- Manufacturing

- Material Handling & Storage

- Material Processing

- Material Fabrication

- Material Paint Shop

- System Assembly with 30-Ton Overhead Crane System

- Panel Build Shop (UL508 Listed)

- Cable & Wire Harness

- VFD Cabinet Assembly Area

- Quality

- ISO 9001:2008 Certified and Registered

- Calibration Certification Capability

- Quality Lab and Equipment Area

- Test and Verification

- Dedicated Mechanical Test Out Area

- Mechanical Assembly Tools, Gauges, Alignment Tools, Vibration & Sound Measurement equipment,

- Electrical Lab support up to 2MWatts to Mechanical Test Out Area

- Electrical Assembly and Monitoring Tools, Gauges, Meters, Meggers, Loggers,

- Hydraulics Assembly Tools, Various Gauges, Various Sensors temperature, pressure & flow sensors, filters

- Training

- In-House Training

- Out-of-House Training

- Operation

- Maintenance

- Calibration

- Documentation

- Commissioning

- All support levels up to Turn-Key

Specifications

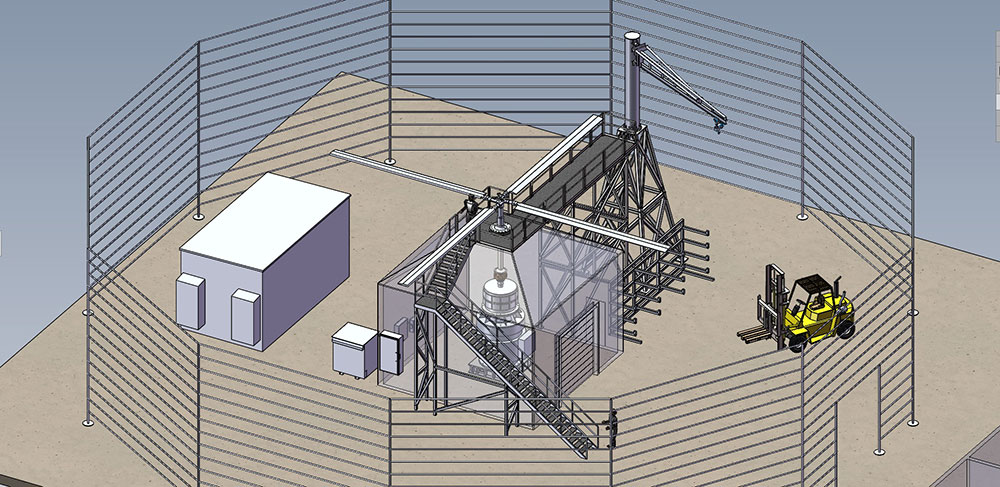

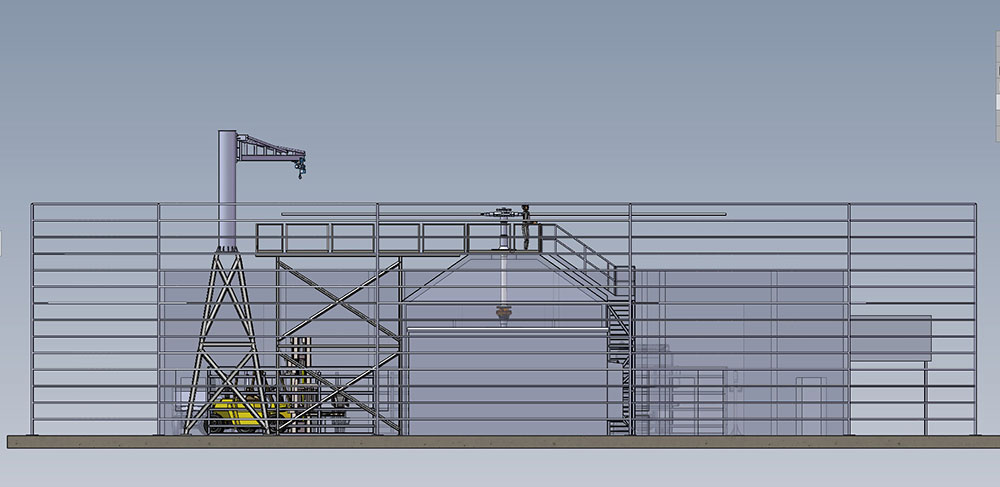

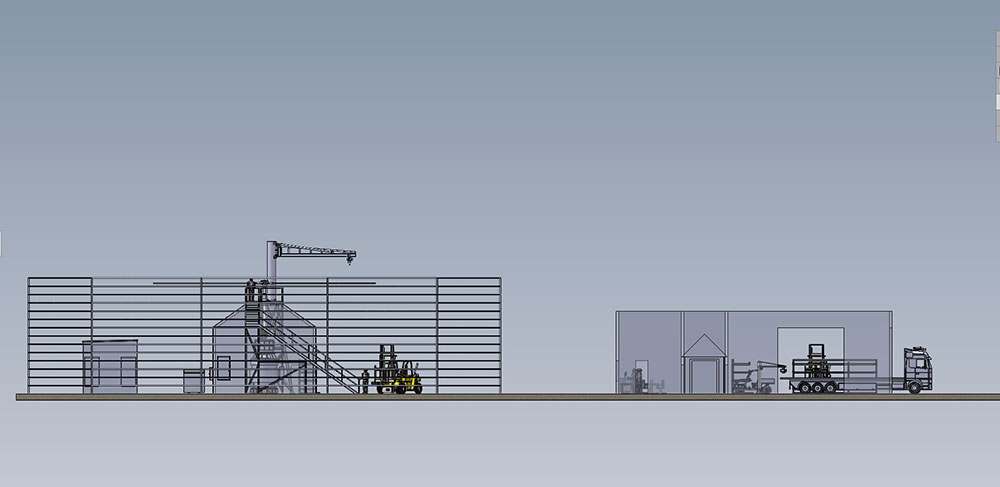

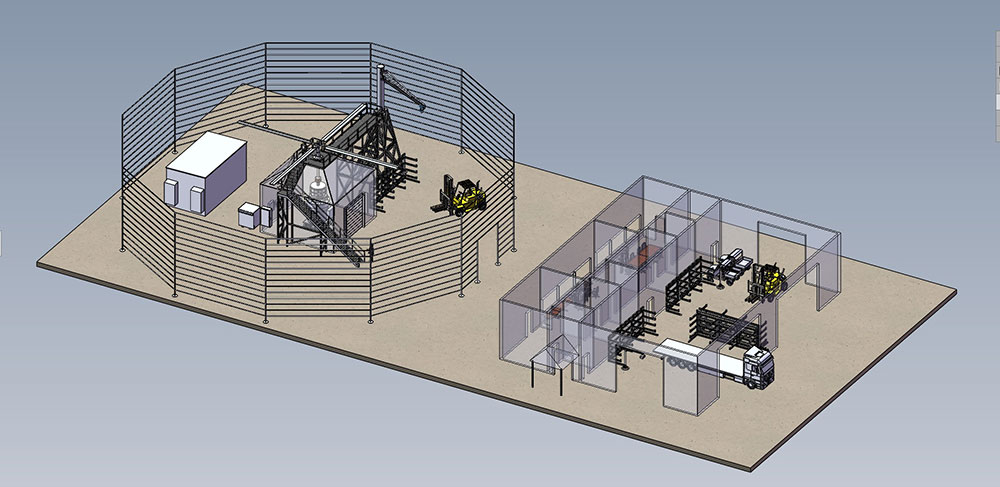

The Whirl Towers physical and performance sizing is subject to the blade specifications. Rotor Power can range from several hundred Hp or kW up to as large as 25,000HP (18,750kW) depending on current or future aircraft blade requirements. The Whirl towers are normally configured for vertical lift blades but can be configured for horizontal push/pull blade/propellers. Additional configurations for Tiltrotor blades with in operation rotation from vertical to horizontal is available.

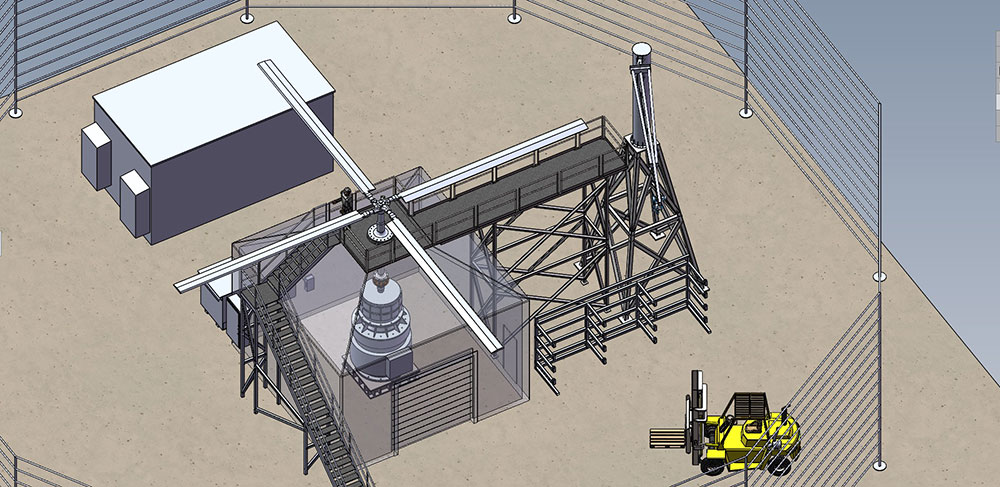

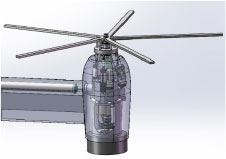

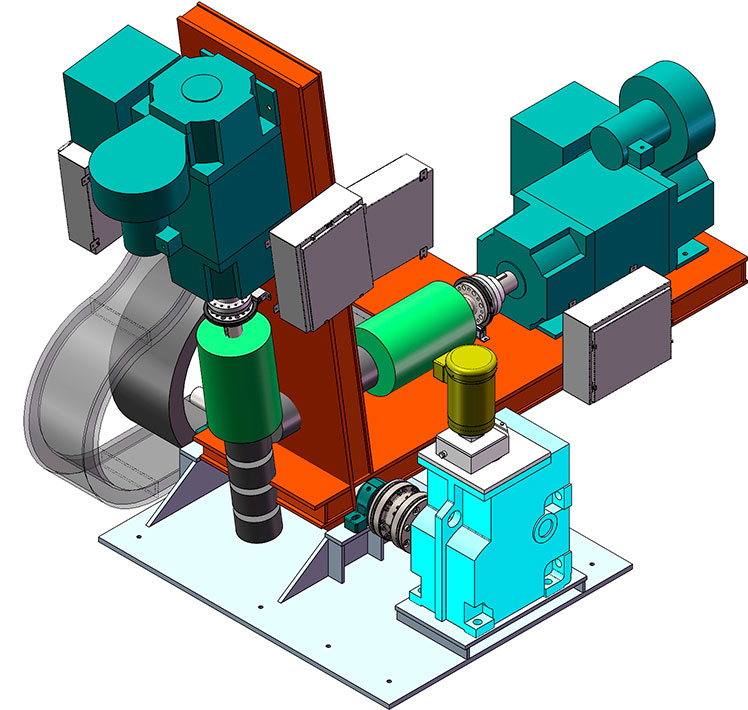

The bi-directional Whirl Tower uses either large direct drive motor or gearbox mounted motor(s) to spin-up rotor blades to applicable test speeds. During the spin up process and while at test speed the system checks for blade balance, alignment, leakage and physical faults. Optional monitoring information is available for Lift Force, Mast Torque, Blade Connection Force, Pitch Force, Temperatures and Pressures.

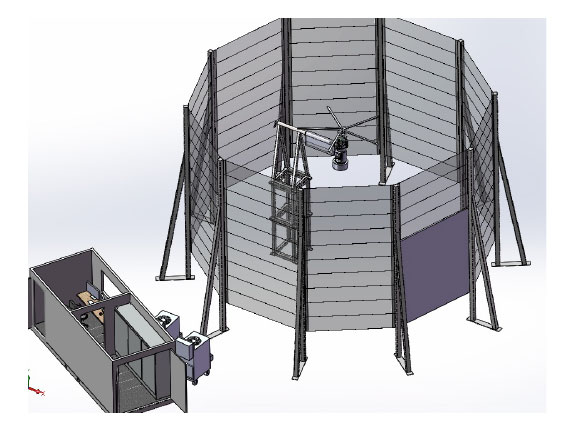

A blade lift system is integrated into the Whirl Tower system to simplify the mounting and removal of Test Blades in a fast-efficient manner. A Safety Screen Guard is installed around the circumference of the Rotor area to protect from blade release.

Typical blade testing uses a master “Gold Standard” Blade. It is attached to the stainless-steel rotor head with pitch control located at the top of the Whirl Tower. Next, Test Blades are connected to the same rotor head to operate at the same time as the Gold Standard blade. The stainless-steel rotor head is instrumented with load cells, torque meter, pitch control distance sensors, velocity sensor, vibration sensors and temperature sensors to monitor the reaction to the rotor head and blades during operation. If required pressure sensors and blade fill system are available for applicable blades. A remote mounted blade tracking laser and/or camera is mounted to monitor the blades as they are operated through the test speeds.

Co-Axial blade test stands are available as per customer specification

Large Whirl Tower Specifications

| Power | Power | Speed | Speed | * Base Speed Blade Length | * Base Speed Blade Length | ** Max Speed Blade Length | ** Max Speed Blade Length | Mast Torque @ Based Spd | Mast Torque @ Based Spd | |

| Model Number | (Hp) | (kW) | Base rpm) | Max (rpm) | (ft.) | (m) | (ft.) | (m) | (lb.-ft) | (N-m) |

| WHRL-0.5k-0.75k/1.5k | 500 | 375 | 750 | 1,500 | 8.6 | 2.6 | 4.3 | 1.3 | 3,500 | 4,740 |

| WHRL-1.0k-0.5k/1.0k | 1,000 | 750 | 500 | 1,000 | 12.9 | 3.9 | 6.5 | 2.0 | 10,500 | 14,230 |

| WHRL-3.0k-250/500 | 3,000 | 2,250 | 250 | 500 | 24.8 | 7.6 | 12.9 | 3.9 | 63,000 | 85,400 |

| WHRL-6.0k-200/400 | 6,000 | 4,500 | 200 | 400 | 31.2 | 9.5 | 15.1 | 4.6 | 157k | 210k |

| WHRL-9.0k-175/350 | 9,000 | 6,750 | 175 | 350 | 35.8 | 10.9 | 17.4 | 5.3 | 270k | 365k |

| WHRL-12k-150/300 | 12,000 | 9,000 | 150 | 300 | 42.0 | 12.8 | 20.5 | 6.3 | 420k | 570k |

| WHRL-20k-125/250 | 20,000 | 15,000 | 125 | 250 | 50.6 | 24.8 | 24.8 | 7.6 | 840k | 1,140k |

** Blade length is based on 0.6 mach blade tip speed rating.

Short Whirl Tower Specification

| Power | Power | Speed | Speed | * Base Speed Blade Length | * Base Speed Blade Length | ** Max Speed Blade Length | ** Max Speed Blade Length | Mast Torque @ Based Spd | Mast Torque @ Based Spd | |

| Model Number | (Hp) | (kW) | Base rpm) | Max (rpm) | (ft.) | (m) | (ft.) | (m) | (lb.-ft) | (N-m) |

| WHRL-5.0-1.75k/12k | 5 | 3.8 | 1,750 | 12,000 | 3.5 | 1.1 | 0.5 | 0.16 | 15 | 20 |

| WHRL-25-1.75k/12k | 25 | 19 | 1,425 | 12,000 | 4.5 | 1.1 | 0.5 | 0.16 | 92 | 125 |

| WHRL-100-250/500 | 100 | 100 | 1,350 | 8,000 | 4.8 | 1.5 | 0.8 | 0.25 | 300 | 407 |

| WHRL-6.0k-200/400 | 300 | 225 | 1,100 | 5,000 | 5.9 | 1.8 | 1.3 | 0.39 | 1,432 | 1,942 |

| WHRL-20k-125/250 | 600 | 450 | 950 | 3,800 | 6.8 | 2.1 | 1.7 | 0.52 | 3,317 | 4,497 |

** Blade lengh is based on 0.6 mach blade tip speed rating.