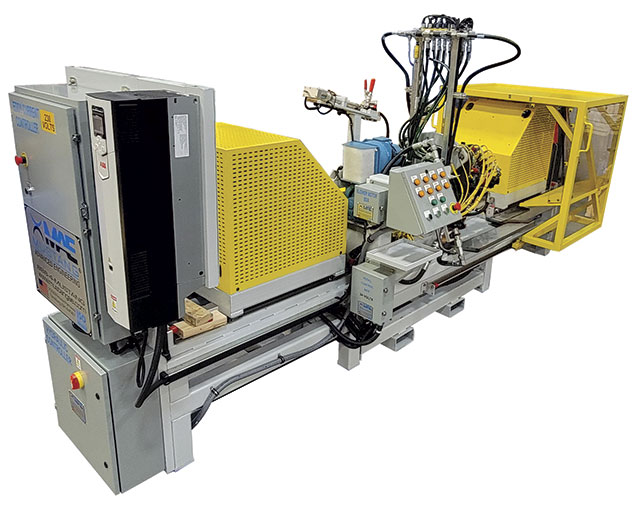

Mustang Advanced Engineering (MAE), a leading U.S. manufacturer of advanced automotive testing systems, has successfully delivered and installed two custom End-of-Line (EOL) transmission dynamometers for NK Parts Industries Inc. / Honda, in Sydney, Ohio.

Challenge:

NKP/Honda, a long-standing re-manufacturer of automotive parts specializing in Honda automatic transmissions, relied on five aging dynamometers to test transmission functionality and quality. When it came time to upgrade their testing equipment, they sought a more efficient, modern solution.

Solution:

MAE responded with a tailored proposal that exceeded expectations. After an in-depth evaluation of NKP/Honda’s testing requirements, MAE engineered and delivered two high-performance, custom EOL test systems to replace the five legacy stations. This upgrade marks a significant technological leap, enhancing both throughput and test quality.

System Features & Capabilities:

TestCell™ Data Acquisition Software: advanced, user-friendly, includes:

- Shift point verification; Full throttle up-shift testing

- Closed throttle downshift testing; Downshift inhibitor validation

- Abnormal noise and vibration diagnostic

- Transmission control system checks

- Leak detection at shaft seals and clutches

- Mechanical binding diagnostics

- Pressure testing (main, clutch, and converter)

Other features include:

- Turnkey installation

• Automated Gear shifting

• Metered transmission oil system

• Fully automated test out sequence

Outcome:

MAE’s two custom-designed systems streamlined NKP/Honda’s quality control process, delivering improved efficiency, precision, and reliability – while consolidating five outdated stations into two cutting-edge, flexible testing platforms.

To download the Project Spotlight (Case Study) brochure (PDF), click here

To download this article as a News Release (PDF), click here